Unyango lomphezulu ludlala indima ebalulekileyo ekuphuculeni ukuqina, ubuhle kunye nokusebenza kweephaneli ze-aluminium, kuquka neephaneli ze-aluminium honeycomb. Iindlela zonyango lomphezulu weepleyiti ze-aluminium ziquka ukugquma nge-roller, ukutshiza ngomgubo, ukutshiza ngeplastiki kunye nezinye iindlela. Indlela nganye ineenzuzo kunye neengxaki ezikhethekileyo, kwaye ukuqonda inkqubo yayo kunye neemveliso ezifanelekileyo kubalulekile ekukhetheni indlela efanelekileyo yonyango kwisicelo esithile.

Iiphaneli ze-aluminium honeycombzisetyenziswa kakhulu kumashishini okwakha, eenqwelo-moya, eelwandle kunye nezothutho ngenxa yobunzima bazo kunye nomlinganiselo ophezulu wamandla ukuya kubunzima. Unyango lomphezulu weephaneli ze-aluminium honeycomb lubalulekile ukuqinisekisa ukusebenza kwazo kunye nobomi benkonzo kwiindawo ezahlukeneyo. Makhe sixoxe ngokunzulu ngeendlela zonyango lomphezulu weephaneli ze-aluminium honeycomb, sihlalutye iingenelo kunye nokungalungi kwe-roller coating, i-powder spray, kunye ne-plastic spray, kunye neendawo ezifanelekileyo zokusetyenziswa kunye nemizekelo.

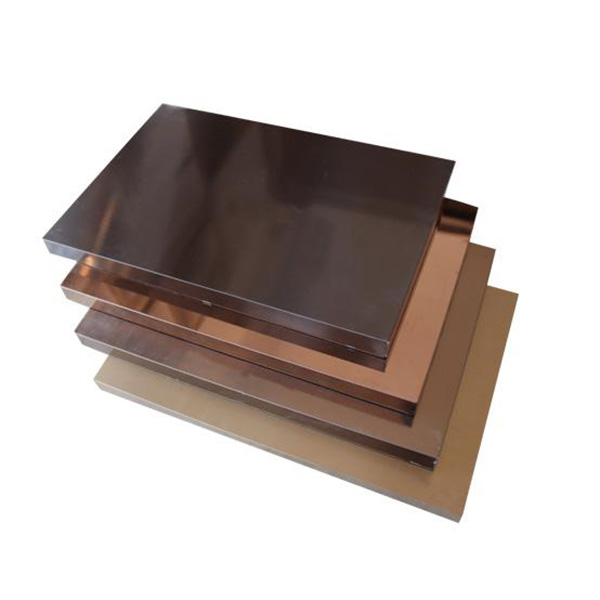

Ukwambatha i-roller:

Ukugquma nge-roller yindlela yokunyanga umphezulu esebenzisa i-roller ukufaka ipeyinti yolwelo kwiiphaneli ze-aluminium honeycomb. Le ndlela inika iingenelo ezininzi, kubandakanya ubukhulu obufanayo bokugquma, ukunamathela okuhle, kunye nokukwazi ukufezekisa unyango oluhlukeneyo lomphezulu, olufana nokungagqwali, ukukhazimla, okanye imiphezulu ethambileyo. Ukongeza, ukugquma nge-roller kunokumelana okuhle nokugqwala kwaye kunokusetyenziswa kwiimo kunye noyilo oluntsonkothileyo.

Nangona kunjalo, i-roller coating inemida ethile. Isenokungafaneleki ukufumana i-coating etyebileyo kakhulu, kwaye inkqubo ingathatha ixesha elide kakhulu kwimveliso enkulu. Ukongeza, i-roller coating ingadinga i-coats ezininzi ukuze kufezekiswe ukugqitywa okufunekayo, nto leyo enyusa iindleko zemveliso.

Indawo efanelekileyo yokusetyenziswa:

I-roll coating ifanelekile kwiimfuno zangaphakathi ezifana nokugqunywa eludongeni ngaphakathi, iisilingi kunye nezinto zokuhombisa ezifuna ukugqitywa okugudileyo nokuthandekayo. Ikwafanelekile kwiimfuno ezifuna imibala kunye nokugqitywa ngokwezifiso, njengeempawu zokwakha kunye nezinto zefenitshala.

umzekelo:

Iiphaneli ze-aluminium honeycomb ezine-roller-coated zisetyenziswa kakhulu kwiiprojekthi zoyilo lwangaphakathi ezikumgangatho ophezulu, kwiindawo zokuthengisa ezikumgangatho ophezulu kunye neendawo zokubonisa, apho ukugqitywa kwekhwalithi ephezulu kunye nokuguquguquka koyilo kubaluleke kakhulu.

Ukwaleka komgubo:

Ukutshiza ngomgubo, okwaziwa ngokuba yi-powder coating, yindlela yonyango lomphezulu equka ukufaka umgubo owomileyo ngombaneiiphaneli ze-aluminium honeycombuze emva koko ucofe umgubo kwi-oven ukuze wenze uqweqwe oluqinileyo nolufanayo. Le ndlela inika iingenelo ezininzi, kuquka ukuqina okugqwesileyo, ukumelana nokuqhekeka, ukukrwela, nokufiphala, kunye nemibala eyahlukeneyo kunye nokugqitywa.

Nangona uboya obuyimpuphu bunezibonelelo ezininzi, kunokubakho imida ekufezekiseni uboya obuncinci kakhulu, kwaye inkqubo yokutshiza inokufuneka ilawulwe ngononophelo ukuze kuthintelwe iingxaki ezifana nexolo le-orenji okanye ubukhulu obungalinganiyo boboya. Ukongeza, iindleko zokuqala zokuseta izixhobo kunye nezixhobo zoboya obuyimpuphu zinokuba phezulu.

Indawo efanelekileyo yokusetyenziswa:

Ugqunywe ngomgubo lufanelekile kwiimveliso zangaphandle ezifana neefacade zezakhiwo, imiqondiso kunye nodonga lwangaphandle olufuna ukumelana nemozulu engcono, ukugcinwa kombala kunye nokuqina ixesha elide. Lufanelekile nakwiimveliso zorhwebo ezifuna ugqunywe ngomgangatho ophezulu oneempawu ezithile zokusebenza, ezifana nokumelana neekhemikhali okanye ukufakelwa kombane.

umzekelo:

Iiphaneli ze-aluminium honeycomb ezinesiphelo esigqunywe ngumgubo zisetyenziswa kakhulu kwiiprojekthi zokwakha ezifuna ukugqitywa okuhlala ixesha elide nokuqaqambileyo, njengezakhiwo zanamhlanje, imifanekiso eqingqiweyo yangaphandle kunye neempawu kwiindawo zasezidolophini.

Ukupenda ngeSpray:

Ukupenda ngeSpray, okwaziwa ngokuba kukupenda ngespray yolwelo, kukusebenzisa ipeyinti yolwelo equlethe amasuntswana eplastiki ukuzeiiphaneli ze-aluminium honeycomb, ethi emva koko inyangeke ukuze yenze ukugqitywa okukhuselekileyo nokuhombisa. Le ndlela inika iingenelo ezinje ngokuchasana okugqwesileyo kwempembelelo, ukuguquguquka kokufikelela kwiintlobo ezahlukeneyo zeenwele kunye namanqanaba okukhazimla, kunye nokukwazi ukwenza iingubo ezineengqimba ezininzi ukuze kuphuculwe ukusebenza.

Nangona kunjalo, i-Spray Painting inokuba nemida ngokwempembelelo yokusingqongileyo, njengoko ezinye iingubo zeplastiki zinokuba neekhompawundi ze-organic eziguquguqukayo (ii-VOC), ezifuna umoya ococekileyo kunye nolawulo olufanelekileyo lwenkunkuma. Ukongeza, ukufikelela kungqamano oluhambelanayo lwemibala kunye nokufana kokugqiba kunokuba ngumceli mngeni kwiinkqubo zokutshiza ngeplastiki.

Indawo efanelekileyo yokusetyenziswa:

Ukubumba isitshizi kufanelekile kwiimfuno ezifuna ukuxhathisa impembelelo kunye nokuguquguquka, njengezithuthi zothutho, izinto zaselwandle kunye nezixhobo zoshishino. Ikwasetyenziswa nakwiiprojekthi zokwakha apho kufuneka kuhlangatyezwane neemfuno ezithile zoyilo, ezifana nokugqitywa okunesitayile okanye imibala.

Umzekelo:

Iiphaneli ze-honeycomb ze-aluminium ezigqunywe nge-coated zisetyenziswa kakhulu kwishishini leenqwelo-moya kwiindawo zangaphakathi ezifana neephaneli zekhabhathi kunye neebhini zokugcina izinto eziphezulu, apho ukugqitywa okulula, okumelana nokuchaphazeleka kunye nobuhle kubalulekile.

Ngamafutshane, iindlela zokunyanga umphezulu weephaneli ze-aluminium honeycomb ziquka ukugquma nge-roller, ukutshiza ngomgubo, ukutshiza ngeplastiki, njl. Nganye ineengenelo kunye neengxaki zayo kwaye ifanelekile kwiindawo ezahlukeneyo zokusetyenziswa kunye neemfuno zokusetyenziswa. Ukuqonda iimpawu zendlela nganye kunye nemveliso ehambelana nayo kubalulekile ekukhetheni unyango lomphezulu olufanelekileyo kwiprojekthi ethile. Ngokuqwalasela ukugqitywa okufunekayo, ukuqina, izinto ezingqongileyo kunye neempawu zokusebenza, abayili kunye nabavelisi banokwenza izigqibo ezinolwazi ukuqinisekisa ukusebenza kakuhle kunye nobuhle beephaneli ze-aluminium honeycomb kuzo zonke iishishini kunye nezicelo ezahlukeneyo.

Ixesha leposi: Agasti-16-2024